BROAD U.S.A. is a privately held company headquartered in New Jersey, supporting the sales and service to our customers in North America. Relying on our innovative and environmental-friendly technology, BROAD U.S.A commits itself to optimize energy efficiency for clients in Commercial, Civil and Industrial markets.

BROAD U.S.A. is committed to the Absorption Marketplace – It is our primary business since we started in 1998

Broad is dedicated and focused on ensuring our owners can always find proper training, service and after sale support with replacement parts and or units.

Broad is committed to the inherent value and flexible solutions that thermally driven absorption plays in our modern world.

We Roll Our Own – Absorbers

Absorption design is our core competency and primary focus . Unlike many current players in the absorption market, Broad designed and created its first absorber in 1988 with its own human capital, hard work, the desire to be the best.

. Unlike many current players in the absorption market, Broad designed and created its first absorber in 1988 with its own human capital, hard work, the desire to be the best.

This homegrown approach has allowed Broad to continue to innovate and lead as the worldwide customer base has grown to over 80 plus counties.

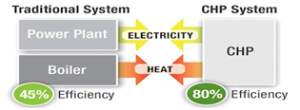

Broad supports CCHP/Co-generation

BROAD has worked closely with the US Department of Energy (DOE) to  assist in some early US-based demonstration deployments of high-efficiency solutions to co-generation heat recovery.

assist in some early US-based demonstration deployments of high-efficiency solutions to co-generation heat recovery.

A prime example of this early cooperation was the demonstration site at Fort Bragg in North Carolina “The 82nd Airborne” back in 2001 BROAD USA is an active member of the USCHP and EPA CHP partnership. Broad is assisting in the August 2012 executive order to deploy over 40GW of CHP by 2020.

Why BROAD Factory Tests Every Chiller as Standard?

Ensures the chiller will yield the operating performance characteristics as designed. It can also be a great opportunity for the operator to learn about the unit which will be cooling or heating the building and to become an expert in the operation of the absorber.

The only way to really validate that the chiller supplied is meeting the design specification requirements. Field testing can be extremely challenging and expensive to replicate. Lowers risk of “system issues” and eliminates field verification of chiller performance which can be very time intensive and difficult to accomplish.

Whole Unit Testing Platform – Our factory acceptance testing (FAT) facility has over 40 test beds for comprehensive performance tests. It is the largest most advanced whole unit testing platform in the world. Broad testing facility has been certified since 1997.

Setting the Bar High on Standards

Broad Absorbers whether they are simple single stage or ultra-high efficiency multi-energy two stage chillers all are designed to the same Stringent Vacuum Standard. The passing test for the Broad standard helium detection test is 10-8 atmospheres of pressure per cubic centimeter of volume per second an industry best in class.

Broad Absorbers whether they are simple single stage or ultra-high efficiency multi-energy two stage chillers all are designed to the same Stringent Vacuum Standard. The passing test for the Broad standard helium detection test is 10-8 atmospheres of pressure per cubic centimeter of volume per second an industry best in class.

Tube material choice and the impact on the longevity of the absorber coupled with a great design and good vacuum is what a modern absorber is all about. BROAD typically is providing higher quality materials such as “oxygen free copper”, CuNi and thicker walls to ensure the chiller meets it 25-year life design cycle without unplanned and costly re-tubing common in other older absorption designs.

A Brief Introduction of BROAD Town

BROAD Town is the headquarters of BROAD Group. It is located in the eastern suburbs of Changsha City, 16 Km from downtown 12km from the airport. Named as “Broad Tech Park” in 1997, it was the first tech park named after a company in China. It is home to dozens of technological inventions that have impacted the whole world, for instance, the world’s first noe-electric exhaust air conditioning, the world’s first fresh air purification machine, the world’s first factory-made sustainable buildings…

“Broad Tech Park” — BROAD Town

BROAD Town covers an area pf 1km², 0.68km² is reserved as ecological protection zone and organic farm. it is a factory with the least factory features. All residential buildings at 0.25 million m² on the campus have adopted 15-20 cm thermal insulation, 3-4 paned windows, external solar shading and fresh air heat recovery machine. BROAD exports air conditioning to more than 80 countries, yet it seldom uses air conditioning itself.

At BROAD Town Organic food,self -processed cerels and edible oils, and reverse osmosis water is all available. Staff have no desires to buy vehicles are awarded monthly, and garbage is classified before recycling, What’s more, the grocery here is unattended, dinning-table and floor is so clean that you will not spot a single grain of rice or piece of paper. All rooms enjoy 100% fresh air with PM2.5 be filtered by 99.9%. Theatre, gym,yoga studio, boutique hotel and 44 statues of the most influential are scattered on the campus, marking BROAD Town a harmonious community between the environmental valve and human value.

BROAD Group Introduction

BROAD Group is an enterprise based on the vision of unique technologies and the mission of preserving. All BROAD products and services are subversion of traditional industries, and are essentially optimizing human life and earth’s environment.

BROAD wholly-owns the following subsidiaries:

BROAD Group was established in 1988, hardhearted in Changsha, Hunan, China and has products in more than 80 counties.

BROAD ENVIRONMENTAL PROTECTION HISTORY

| Year | Events |

|---|---|

| 1992 | Invented China’s first CFC-free direct-fired non-electric air conditioning |

| 1997 | Invented the world’s first plate heat exchanger for non-electric air conditioning with energy efficiency increased by 40% |

| 1998 | Release the BROAD Declaration , advocating “fighting against low energy efficiency and material waste to the fullest, extending product lifespan to the longest” Pesticide and fertilizer prohibited in BROAD Town Implemented the water and electricity metering systems for BROAD staff |

| 1999 | Invented the world’s first non-electric zero emission air conditioning powered by exhaust gas from turbine Recommended low-load design to customers in product brochures to advocate energy conservation even at the risk of receiving complaints |

| 2002 | BROAD Organic Farm was developed to provide organic food to staff |

| 2003 | Released the BROAD Values to advocate “environmental protection is more important than profit” |

| 2004 | Invented the world’s first Packaged Water Distribution System with operational energy decreased by 70-85% for cooling water and chilled water Initiated the annual energy consumption check policy for all customers with open reports The world’s first company to take dispute risk by showing energy efficiency on chiller’s control panel |

| 2005 | Translated and published 250,000 copies of YouthXchange , an environment guideline of UNEP |

| 2006 | Translated & published the 780-page Living in the Environment , an English environment encyclopedia |

| 2008 | China’s first thoroughly-renovated community with all buildings at BROAD Town retrofitted with 15cm thermal insulation, 3-paned windows, external solar shading and heat recovery fresh air Invented the world’s first clean fresh air machine, recovering exhaust heat by 80% and filtering PM2.5 by 99.9% |

| 2009 | Invented the world’s first factory-made sustainable building (BSB) that saves energy by 80% Invented the world’s first Life Phone (Air Monitor) to detect PM2.5, CO2, etc. Completely replaced detergent with caustic soda and adopted reverse osmosis water as drinking water at BROAD Town |

| 2010 | Provided central air conditioning system and operation services to all 250 pavilions at World Expo Shanghai, cutting 73,000 tons of CO2 emissions, which equals to planting 4 million trees Built a sustainable building demo for The United Nations Framework Convention on Climate Change (COP16, Cancun) |

| 2011 | BROAD chairman was awarded the “Champions of the Earth” by the UN for his contributions to energy conservation |

| 2012 | UN Secretary General cited BROAD as the only energy conservation case in the “RIO +20 Declaration” The Oval Mountain Organic Farm was built in Xiangyin County, gradually increase the food organic rate of staff to 80% Launched the 8-catergory garbage sorting system. Low Carbon Commute Incentives for Staff was carried out to encourage car-free staff |

| 2013 | BSB was awarded the CTBUH (Council on Tall Buildings and Urban Habitat) Innovation Award for its contribution to innovative environmental conservation Installed solar panels for all factory roofs (230,000 m2) in BSB factory |

| 2014 | BROAD chairman was awarded the World’s Top 25 Eco-Innovators by Fortune Magaine BROAD Recycled Oil Company obtained the qualification to utilize 30% of national waste mineral oil |

| 2015 | To make building an eternal wealth, BROAD started the invention of core tubular stainless steel slab and stopped production of steel structure during the same year |

| 2016 | To extend the lifespan of air-conditioning to 60 years and extend the lifespan of heat exchange tube to unlimited , BROAD replaced brass heat exchange tubes and stainless steel heat exchange tubes with titanium tubes |

BROAD Mission

For Humanity’s Future BROAD’s Unique Building Energy Conservation Technology Protects the Earth BROAD’s Unique Clean Air Technology Protects Mankind

BROAD Vision

Only develop unique technologies Only provide products and services beneficial to the earth and humanity

BROAD Faith

The Farming Law.

Farming matches reaping and farming precedes reaping. To reap every year, one must farm every year.

BROAD Tenet

Perfect oneself and be outstanding, restrain oneself and be absolutely obedient

BROAD Moral Line

7 ”Nos” & 1 ”Without”

No environmental pollution, No technology plagiarism No customers cheating, No vicious competition, no chain debts, No tax dodging, no bribery, and Without malicious conscience

BROAD Employee’s Moral Line

10 ”Nos” & 1 ”Without”

Ten (10) ”Nos” & One (1) ”Without” No malfeasance, no indolence, no promise breaking, no lie, no clique, No betray, no bribery, no avarice, no waste, no pollution Without sourness

The core values of BROAD include responsibility to our environment which nurtures us, responsibility to humanity which inspires us, responsibility to our customers who support us, and responsibility to our employees who dedicate their energy and creativity for all of us.

For the environment, everything we do is from the perspective of sustainability: Increasing energy efficiency, reducing energy consumption, reducing energy costs, and reducing consumption of materials.

For humanity, sustainability is wired into the DNA of the full spectrum of BROAD’s diverse product lines: Non-electric chillers, sustainable structural material, clean air machines, prefabricated negative pressure rooms, and many other products. BROAD reduces our customers’ carbon footprint, and charts the way to a future of sustainable cooling and heating, building construction, and air purification.

For our customers, we aim to be an enterprise one is proud to do business with. For many companies, perhaps profit is most valued. At BROAD, our aim is to be distinguished by excellence in products and service: to conceive of and make products no one else can make, and to offer a level of service no one else can provide. So what sort of enterprise does that make us?

In an era of social transformation plagued by vague moral standards

BROAD adheres to the “Principle of 7 Nos and 1 Without”: No environmental pollution, no technology theft, no cheating, no vicious competition, no chain debt, no tax dodging, no bribery, and without malicious conscience. BROAD believes morals are more important than competition, and responsibility is more important than growth.

How are our values reflected in our core product lines?

In our era of global warming, environmental deterioration, and ozone depletion, BROAD continues to innovate and invest in our absorption chiller, now in the 12th generation, to capture waste heat for power and contribute zero ozone depletion, because we believe that environmental protection is more important than profit.

In our era of deteriorating air quality, BROAD has abandoned our ROI model and invested huge sums in air purification systems that provide 100% fresh air with no recycled air, unlike the 70% return air/30% fresh air of most conventional air handlers. In our era of pandemic caused by COVID-19, BROAD has developed a Negative Pressure Isolation (NPI) facility by combining our expertise in prefabricated stainless steel buildings with our air purification prowess to develop a treatment center than can be built in days, and protects medical staff and enables them to treat patients in the safest environment possible. Another innovating product others cannot make, backed by service others cannot provide, because we believe that human health is more important than profit this year or next.

In our era of accelerating urbanization, BROAD has brought for a new structural material made of hardened stainless steel: B-CORE. Tall buildings can now be built without concrete or carbon steel, which together account for over 12% of total global emissions. B-CORE challenges conventional building traditions, providing the more energy efficient, healthiest buildings which have an almost unlimited lifespan as stainless steel is so non-corrosive. BROAD poured huge investments into this technology, because the future of the human race is more important than the future of us an individuals.

Every day, BROAD aims to demonstrate our loyalty to our customers, fairness to our vendors, and dedication to our employees. Long term relationships are more important than gains or losses.

See our catalog page 45. [

See our catalog page 45. [