Project Background

Baystate Health is a nonprofit, integrated health care system headquartered in Springfield, Massachusetts, serving over 800,000 people throughout Western New England. The system has 4 hospitals, over 80 medical practices, and 25 reference laboratories. Baystate Medical Center (BMC) is the biggest hospital in Baystate Health systemwith 716 beds. It is an independent academic medical center and a training site for the University of Massachusetts Medical School.

BMC is also the community’s major referral hospital, providing the highest level of care for conditions such as cancer, acute and chronic cardiovascular illness, nervous system illness, digestive illness, and other diseases that affect the major organs. In 2016, U.S. News & World Report ranked BMC the third best hospital in Massachusetts. BMC has over 1,100 medical staff physicians, 10 residency training programs and 99 clinical trials underway.

System Background

In 2016, Baystate Health initiated a $27 million CCHP plant that provides non-grid energy sources to critical facilities in the event of power loss during a disaster. The CCHP plant is part of the Housing & Urban Development (HUD) National Disaster Resilience Competition, a program that awarded the City of Springfield over $17 million to facilitate disaster resiliency.

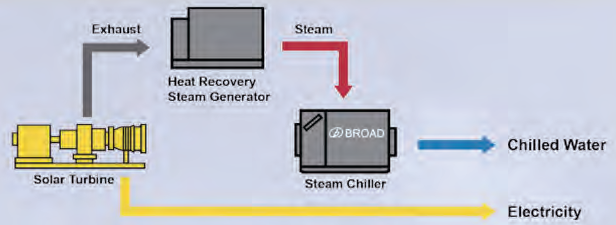

The trigeneration power plant is located at the largest level I trauma center in western Massachusetts, replacing an 80-year-old facility. The plant includes a 4.6-megawatt gas turbine to produce 80% of its own power, bringing much needed relief to the stressed energy grid. The steam, the byproduct of the combustion associated with the spinning natural gas engine, is also used for sterilization, to heat the hospital and to drive a BROAD two-stage steam absorption chiller for summer cooling.

Baystate Medical Center CCHP Plant

Project Value

The CCHP system produces 80% of the electricity and 98% of the steam utilized at Baystate. The system is capable of operating in island mode for at least 30 days uninterrupted during a utility crisis. The BROAD absorption chiller uses waste heat from the trigeneration plant, increasing Baystate’s energy efficiency by roughly 25% and saving 3,400MWh/year electricity for cooling*. The CCHP system reduces annual utility costs by a minimum of 1.45 million dollars. The system reduces greenhouse gases by 4,507 tons, which is equivalent to the carbon sequestered by 74,524 trees grown for 10 years.

Baystate Medical Center CCHP System Diagram

Equipment Information

Generator

Model: Solar Gas Turbine Mercury 50

Fuel: Natural gas

Power output: 4,600 kW

Electrical Efficiency: 38.5%

Steam Production: 13.1-103.9 klb/hr

BROAD Absorption Chiller

Model: Two-stage steam chiller BS300

Cooling Capacity: 925 RT

Heat Source: Steam from Heat Recovery Steam Generator

Why CCHP in Hospital?

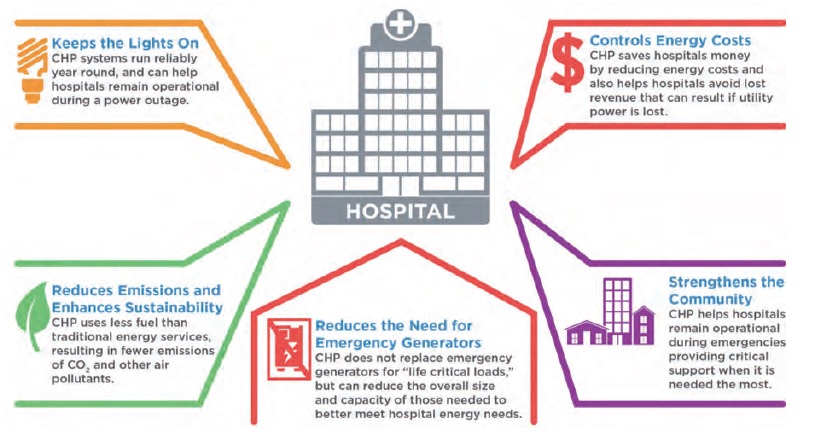

More than 220 hospitals in the U.S. operate CCHP systems. Hospitals are ideal candidates for CCHP systems. The high and constant 24/7 demand of electric power, heating and cooling allows CCHP system to reduce energy costs, increase energy efficiency and reliability, and improve environmental performance.

Project Gallery

Contact Us Today