Project Background

The Gansevoort Meatpacking is an iconic hotel that has been called New York City home since 2004. The 186-room hotel features a full-service ground-floor restaurant, a year-round rooftop bar and restaurant, a 45-foot heated outdoor pool, and indoor and outdoor space where guests can enjoy unobstructed, 360-degree views of the Manhattan skyline.

Located on Ninth Ave and 13th Street, Gansevoort is an anchor in Manhattan’s vibrant Meatpacking District, which has transformed from an industrial district into a hub for fashion, design, culinary excellence, and the arts.

The property is just stepping away from the Hudson River, the High Line, Little Island, premium shopping and dining, the Whitney Museum of American Art, Chelsea Market, and more. The property has completed a top-to-bottom renovation touching all floors, accommodations, and public spaces.

Project Description

This gas-fired absorption chiller system includes two 66-ton cooling capacity BROAD absorption chillers for heating and cooling the building with the COP 1.35 and absorbers can provide heat up to 200F with 0.93 COP.

The chiller would provide more efficient cooling at off-peak hours and at low operating costs when compared to already installed chillers.

BROAD maglev chiller would be replacing the job of the previously installed chillers during summertime and act as the sole cooling provider while the other two chillers would be used for heating purposes.

Project Highlight

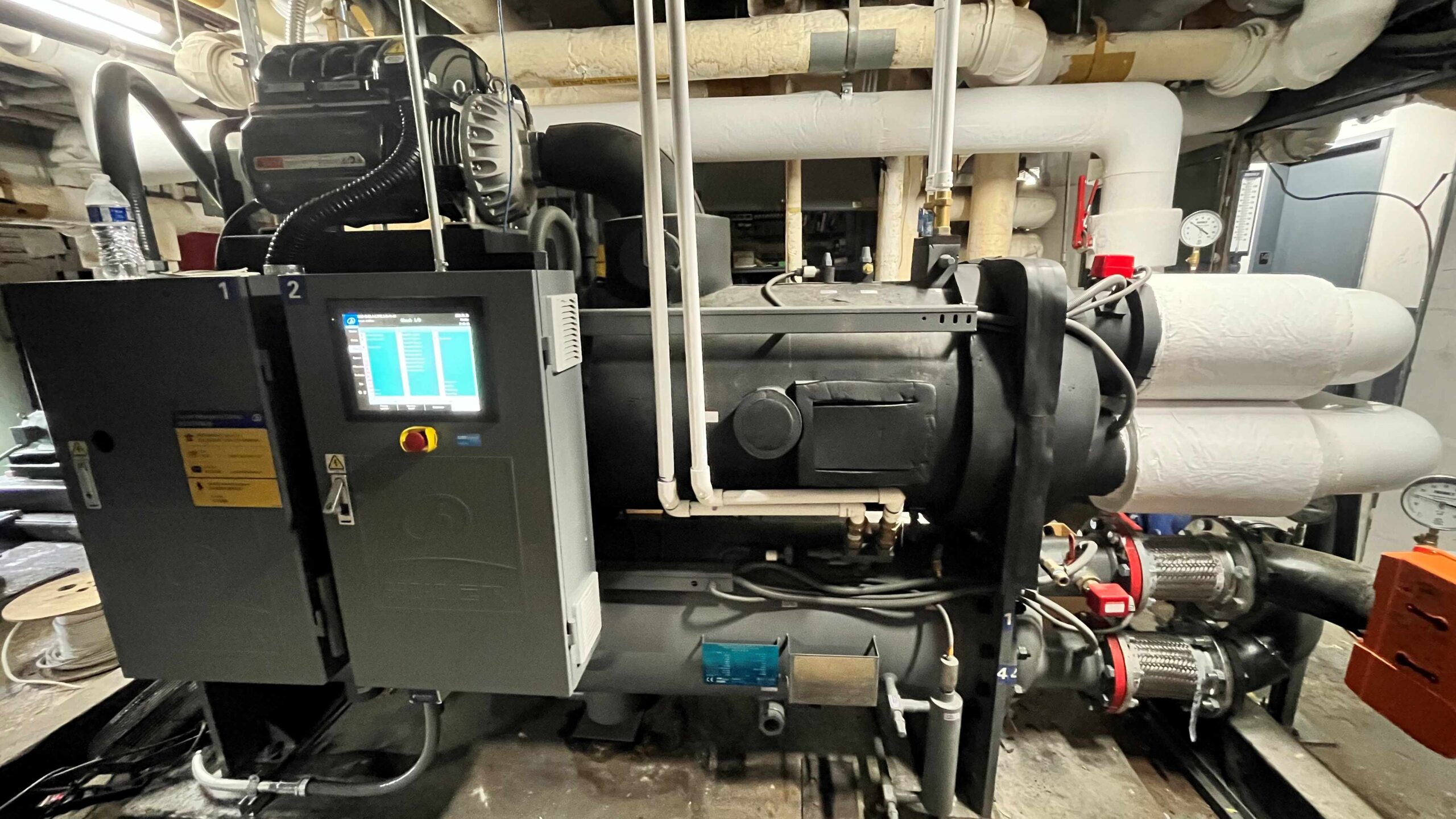

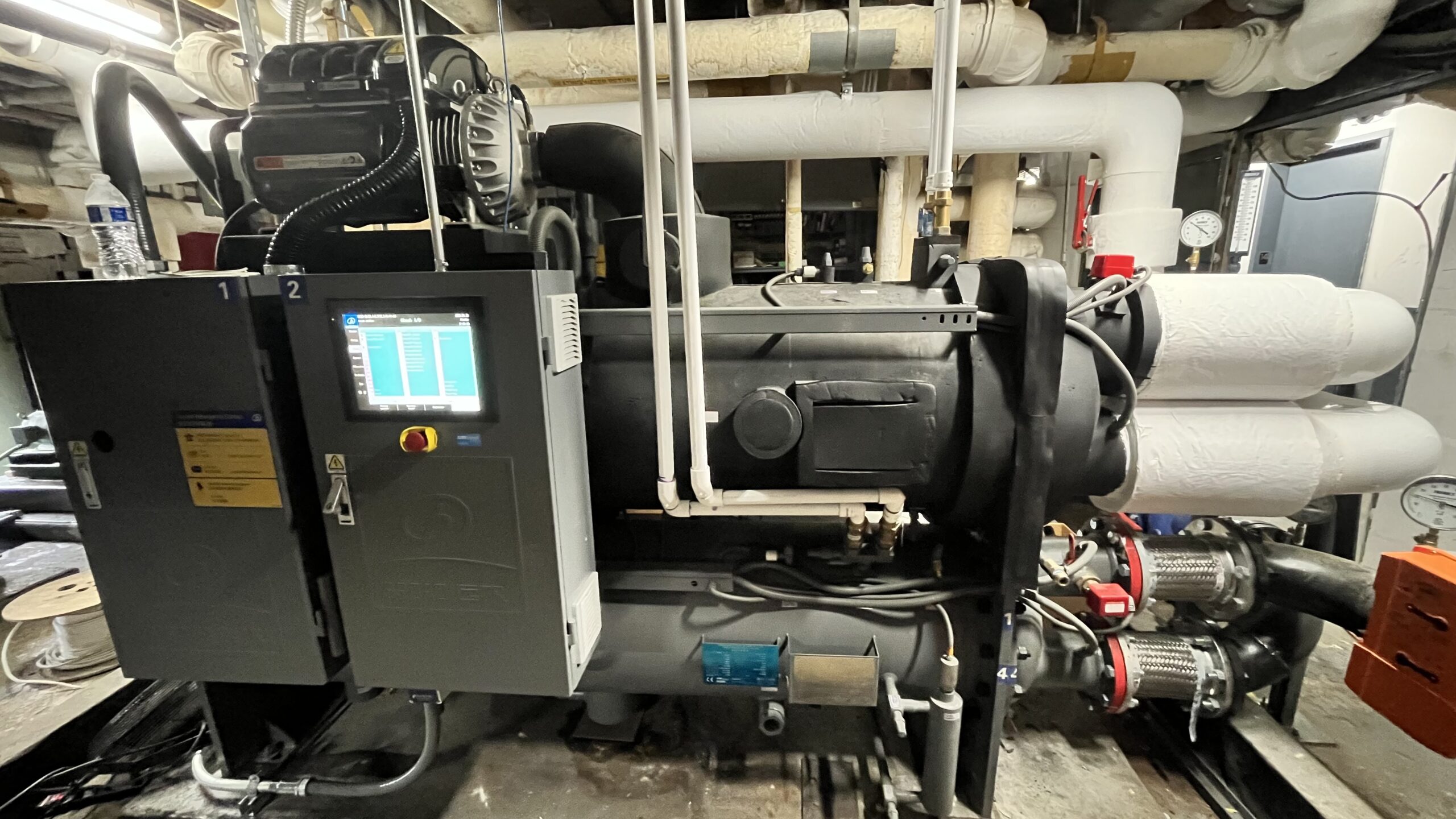

Selected as a general contractor, we designed and built this project and successfully commissioned the chiller. We installed BROAD’s maglev chiller in the hotel, which allows the compressor to operate without using oil for lubrication and making it frictionless.

It is equipped with multiple two-stage centrifugal Danfoss compressors. No oil enters the evaporator or the condenser, which reduces energy losses due to friction and increases the heat transfer efficiency of the chiller. The built-in Variable Speed Drive on the motor allows the compressor to operate much more efficiently at partial loads. The oil-free system also eliminates the need for oil maintenance, resulting in operations and maintenance savings.

The new BROAD chiller’s IPLV is 0.35kw/Ton. Additionally, it consists of modular and multipiece rigging through regular elevators and doors. The single piece of the new machine weighs less than 2000 lbs. leading to reduced capital cost. The oil-free maglev chiller is ideal for building retrofitting or new construction projects.

Project Value

The maglev chiller has a low operating cost and is only going to be running solely for the summer season, thereby lowering energy consumption, and fulfilling its Environmental and Social responsibilities.

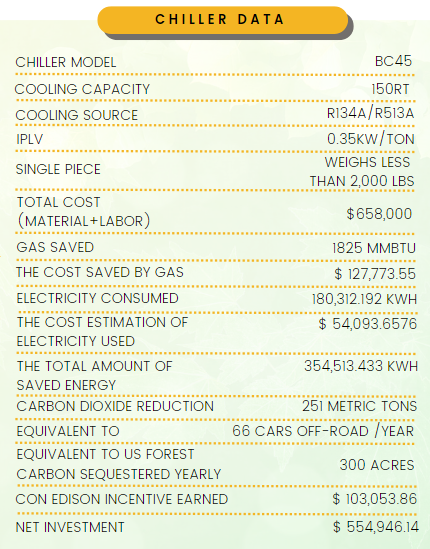

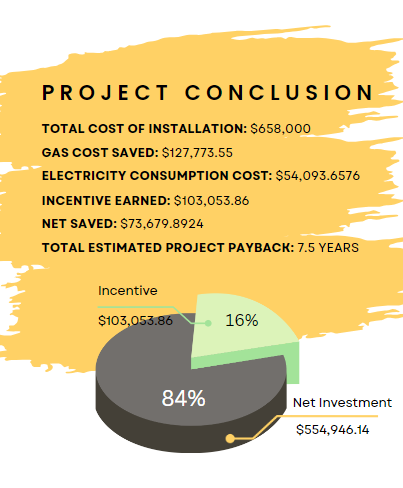

It saves 1825MMBTU/534,825.625kWh of fuel by reducing the usage of absorption chillers in the summer season, thus the cost saved by replacing the absorption chillers is $ 127,773.55 and we are using 180,312.192 kWh of electricity.

As a result of this, a total of 354,513.433 kWh is saved. System carbon dioxide reduction is 251 Metric tons* which is equivalent to 66 cars pulled off from the road every year* or 300 acres of U/S forest carbon sequestered per year*.

* Results are based on the US EPA CHP Energy and Emissions Savings Calculator, which may vary from the actual operation data.

Project Data Breakdown

Project Conclusion

Equipment Information

BROAD Absorption Chiller

Model: BC45 BRAOD Maglev Centrifugal Chiller

Cooling Capacity: 150 RT

Cooling Source:Refrigerant R134A/R513A

Operational Value

- To achieve the Con Edison incentives, a custom calculation for the chiller was done.

- For easy transportation and installation, a rigging plan was developed to make sure that the machine goes through the regular door and fits in a regular elevator.

- The machine was brought up in pieces and put together.

- This results in lesser labor costs and great convenience for the customer.

Project Gallery