Project Background

MedImmune is the biologics and biotechnology research and development arm of the pharmaceutical and biopharmaceutical manufacturer, AstraZeneca. In 2007, Astra-Zeneca bought the company for a whopping $15.6 billion — one of the largest biotech deals of that decade.

MedImmune has more than 150 product pipelines in Oncology, Cardiovascular, Renal and Metabolic, Respiratory and Immunology and other diseases.

MedImmune employs over 3,500 employees in the D.C area with over $1.81 billion in revenue in 2017, making it the largest employer in the local industry, according to Washington Business Journal data. Its nine-story Gaithersburg headquarters comprises 1.27 million square feet.

MedImmune’s impact on Maryland’s biotech corridor is arguably unparalleled, pioneering innovation and discovery locally with a robust alumni network embedded within the industry.

System Background

With a goal of reducing its carbon footprint, decreasing facility operational costs, increasing power reliability and increasing resiliency against outages, MedImmune deployed a CCHP system in its Gaithersburg campus.

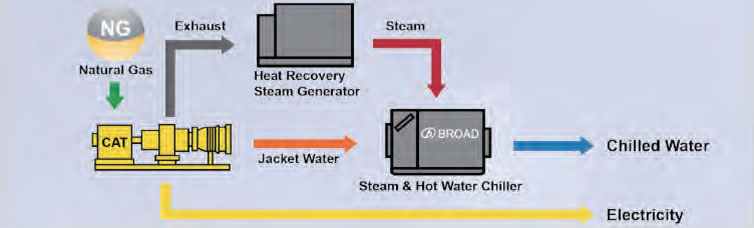

The system includes 2.5 megawatts of natural gas powered generation set, steam and hot water heat recovery heat exchangers and a 500-ton BROAD multi-energy absorption chiller. Also a paralleling switchgear was added to tie together two existing 3 megawatt diesel generators to the CCHP systems. This allows the MedImmune campus to respond quickly to an immediate outage, as well as sustain long-term generation during a prolonged outage event by transitioning to island mode Exhaust gas from the CCHP system feeds a heat recovery, steam generator (HRSG) boiler to produce steam. The absorption chiller uses this steam and jacket hot water to produce chilled water, maximizing the year-round CCHP energy efficiency and reducing carbon emissions. ISO50001

In 2014, MedImmune Gaithersburg campus qualified for a Silver Superior Energy Performance (SEP) award, a certification for industrial facilities based on ISO50001’s global energy management system standards.

Project Value

The BROAD multi-energy chiller realizes the step-by-step utilization of waste heat, achieving a comprehensive energy efficiency of approximately 83%, saving nearly 3,500 MWh per year electricity consumption for cooling. The natural gas backup of absorption chiller ensures the redundancy and consistency in the chilled water loop, thus when the generator is intelligently switched off based on the control system’s analysis, the absorption chiller can smoothly change to direct-fired mode to ensure stable operation.

The BROAD absorption chiller is able to meet 80~100% of the building’s cooling requirement, allowing the electric chillers to be turned off at the current stage. Compared to the central station power plant, annual energy savings from the CCHP system: 11,428 MMBtu of fuel*. System annual greenhouse gas emissions reduction: 1,837 metric tons of carbon dioxide equivalents, which is equivalent to carbon sequestered by 30,310 trees grown for 10 years*.

System simple payback period: 4.5 years.

Equipment Information

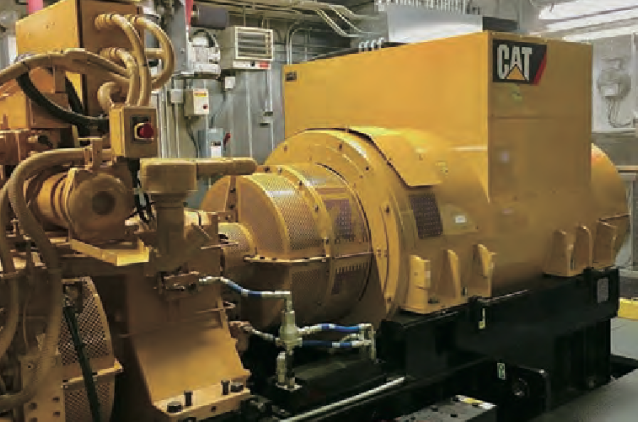

Generator

Model: CAT G3516H

Fuel Type: Natural Gas

Maximum Continuous Rating: 2,027 kW

Maximum Electrical Efficiency: 44.7%

BROAD Absorption Chiller

Model: Multi-energy BHS250

Cooling Capacity: 500 RT

Heat Source: Engine jacket water & Steam from Heat Recovery Steam Generator

Project Gallery