Project Background

The University of Minnesota, Twin Cities (hereafter “the University”) is a public research university in the Twin Cities of Minneapolis and Saint Paul, Minnesota. The Twin Cities campus is the oldest and largest in the University of Minnesota system and has the sixth-largest main campus student body in the United States, with over 50,000 students in 2019-2020, which is organized into 19 colleges, schools, and other major academic units.

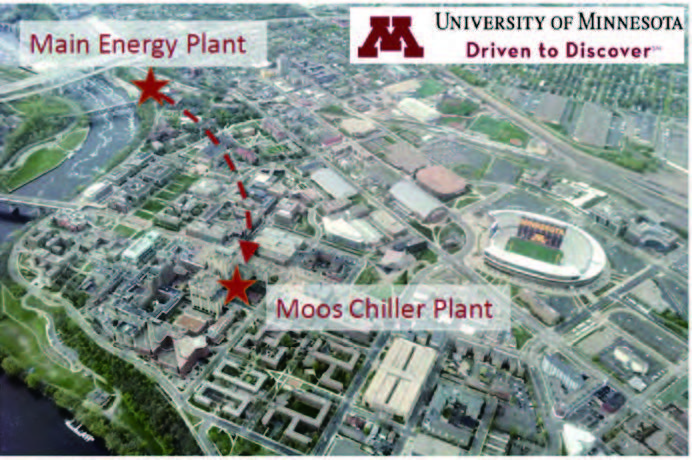

Malcolm Moos Health Sciences Tower (hereafter “Moos Tower”), as the tallest building and the largest and most consistent chilled water user on campus, is located on the east bank of the Mississippi River near downtown Minneapolis. It is named after Malcolm Moos who was the president of the University from 1967 to 1974. Inside Moos Tower are labs, classrooms and faculty offices for the College of Dentistry.

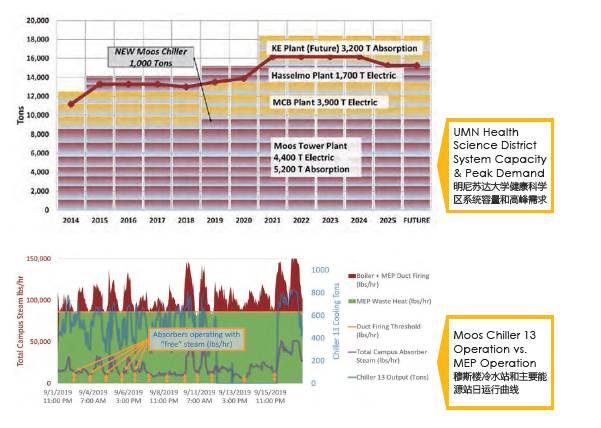

To meet the growing demand of chilled water and to further reduce the peak electric demand at Moos Tower Chiller plant for the health sciences district, the University plans to add a 1000-ton steam absorption chiller to provide additional cooling capacity for the Tower and the neighboring buildings.

System Background

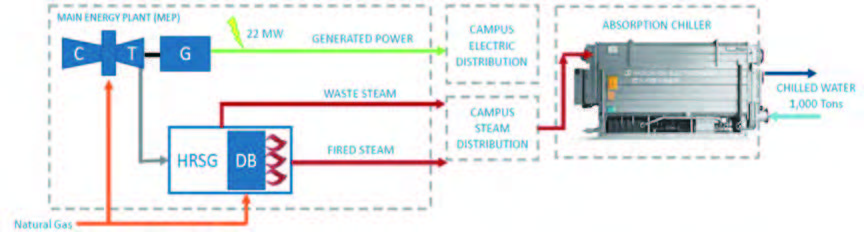

Inside the chiller plant at Moos Tower, there are nine existing electric chillers, and four steam driven absorption chillers to provide chilled water. The peak cooling load for this district is estimated to be over 10,000 tons. High pressure steam, coming from a 24MW gas turbine in the campus main energy plant, is distributed and supplied through the campus steam grid.

The added BROAD steam absorption chiller provides 1,000 tons of cooling to help alleviate the cooling load pressure during the peak cooling season, as shown in the cooling load projection below.

Project Highlight

The University issued an RFP (Request for Proposal) in March 2018, and the new absorption chiller was installed and in operation for the cooling season in 2019. Heavy rigging and tight clearance space, mandatory factory performance testing and onsite field acceptance performance testing with bonus and penalties made this project a challenge, meanwhile, gave chiller manufacturers an opportunity for demonstration and statement.

After extensive review and evaluation by the University, BROAD was awarded to be the absorption chiller supplier for its well-proven rigging solution, experience in performance testing, the high reputation in superior energy efficiency and product quality, as well as various installation references in US.

1. Four-pieces Supply and Reassembly Onsite

Moos Tower mechanical room is 50ft below grade, posing rigging challenges for equipment. BROAD absorption chiller was knocked down to four separate sections (after passing the factory performance testing) with an individual rigging frame that enabled vertical rigging from the ground level sidewalk opening and then horizontal rigging to the basement mechanical room of the Tower building. Then the chiller was reassembled onsite by the BROAD service team to deliver the desired cooling performance.

2. Factory and Onsite Performance Test

Factory acceptance testing is an essential part of BROAD’s standard scope of supply, and the customers are warmly welcomed to the factory to witness. In this project, the BROAD chiller is customized per requirements (four-pieces supply and engineer-specified tube metallurgy) to provide 40oF (4.4oC) chilled water. In the presence of the University customers and engineers, the BROAD steam absorption chiller has successfully passed all the required performance tests, including ZERO-tolerance full load capacity and performance tests, and part-load capacity and performance tests (at specified load points) per the AHRI-560-2000 standard.

Project Value

The newly installed steam absorption chiller started operation in May 2019, and has already presented attractive economic and environmental benefits to the health sciences district and campus. Absorption cooling became a key element to balance the trigeneration system and maximize its value. Compared to the electric centrifugal chiller, absorption chiller with waste steam heat has a 40% lower CO2 footprint and 80% lower fuel cost. In this iconic project, BROAD again demonstrates its capabilities, flexibility and innovative solutions in providing high quality and reliable chiller products with customization.

Equipment Information

BROAD Absorption Chiller

Model: Two-stage steam chiller BS400

Cooling Capacity: 1,000 RT

Heat Source: Steam from central energy plant

Onsite Rigging

Onsite Performance Testing

Main Energy Plant & Moos Chiller Plant