Project Background

The Pinellas County Jail is located on 54 acres of land in central Pinellas County, and adjacent to the Criminal Justice Center. It is the only jail in Pinellas County and serves all law enforcement agencies. The jail complex houses an average daily population topping 3,000 inmates, including pretrial and sentenced offenders. The Pinellas County Jail is the 28th largest jail in the nation, and is nationally accredited by Detention and Inmate Healthcare professional associations.

System Background

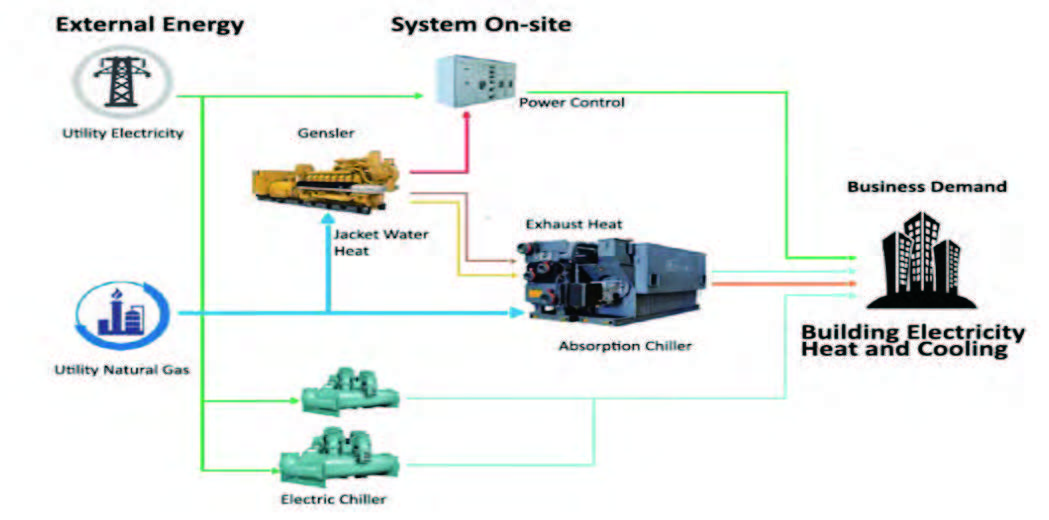

Due to Florida’s unpredictable weather and yearly hurricanes, in 2015, the Pinellas County Commission approved a nearly $100 million upgrade project renovating parts of the Pinellas County Jail. Phase I of this upgrade project includes the design and construction of two new buildings. One houses the facility’s kitchen, laundry room and central energy plant; the second new building houses the warehouse operations, facilities maintenance and a warehouse. This project was completed in 2018 and was awarded the Best Overall Project by Design- Build Institute of America Florida in 2019. The new central energy plant for Pinellas County Jail is designed with a state-of-the-art CCHP system including a 2MW gas engine and a 1,000-ton BROAD multi-energy absorption chiller. Phase II project would employ an identical system and already reserved the space. Instead of only operating during an emergency or outage, the CCHP system is running 24/7 all year round to lower energy costs and improve efficiency. The BROAD absorption chiller can provide a maximum of 1,000 tons of cooling, in which 500 tons of “free” cooling is from reclaiming the waste heat from engine exhaust and jacket water. The jacket water is also used to preheat the hot water and steam systems. The plant also includes two 1,500-ton centrifugal chillers with space for expansion. Unlike the common CCHP system, the chiller can also use natural gas to provide a supplementary energy source and full back up. Thus when the engine is under maintenance or shutting down, the chiller alone can still provide chilled water to serve the facilities, providing redundancy and resiliency for the whole system.

Project Value

The BROAD multi-energy chiller realizes the step-by-step utilization of waste heat, achieving a comprehensive energy efficiency of approximately 83%, saving nearly 3,500 MWh per year electricity consumption for cooling. The natural gas backup of absorption chiller ensures the redundancy and consistency in the chilled water loop, thus when the generator is intelligently switched off based on the control system’s analysis, the absorption chiller can smoothly change to direct-fired mode to ensure stable operation.

The BROAD absorption chiller is able to meet 80~100% of the building’s cooling requirement, allowing the electric chillers to be turned off at the current stage. Compared to the central station power plant, annual energy savings from the CCHP system: 11,428 MMBtu of fuel*. System annual greenhouse gas emissions reduction: 1,837 metric tons of carbon dioxide equivalents, which is equivalent to carbon sequestered by 30,310 trees grown for 10 years*.

System simple payback period: 4.5 years.

Equipment Information

Generator

Model: CAT G3516H

Fuel Type: Natural Gas

Maximum Continuous Rating: 2,027 kW

Maximum Electrical Efficiency: 44.7%

BROAD Absorption Chiller

Model: Multi-energy chiller BZHE300

Cooling Capacity (CCHP/Max): 500/1,000 RT

Heat Source: Exhaust, Hot Water, Natural Gas

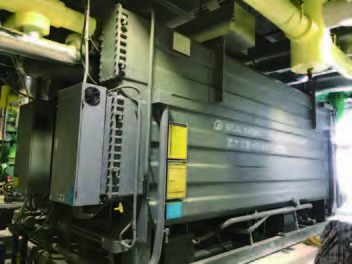

Project Gallery