BZ Model, Direct Gas Fired

- Capacity: 30-3300 ton

- Gas Pressure: 2.3-7.3 Psi (Standard)

- Dual Fuel Burner (Gas and Oil, Low NOx, <10ppm)

- Cooling / Heating / Domestic Hot Water

BS Model, Steam Driven

- Capacity:30-3300 ton

- Steam Pressure: 60 – 150 Psi

- Chiller Come With Steam Valve

- Cooling Only

BE Model, Exhaust Driven

- Capacity:40-3300 ton

- Exhaust Pressure Drop: 3 – 8 Inch W.C.

- Exhaust Temperature: 536-990F

- Cooling / Heating Only

BH Model, Hot Water Driven

- Capacity:30-3300 ton

- Hot Water Temperature: 280 – 356 F

- Provides Hot Water Valve

- Cooling Only

BDH Model, Single Stage Hot Water Driven

- Capacity: 30-1800 ton

- Hot Water Temperature: 160-220 F (Standard)

- Hot water Valve

- Cooling Only

BDE Model, Single Stage Exhaust Driven

- Capacity:30-1163 ton

- Exhaust Temperature: 450 – 600 F

- Cooling Only

BDS Model, Single Stage Steam Driven

- Capacity: 30-2000 ton

- Steam Pressure: 6.0-60 Psi (Standard)

- Offer Steam Valve

- Cooling Only

BZE Model, Exhaust and Direct Fired

- Capacity: 30-3300 ton

- Gas Pressure: 2.3-7.3 Psi (Standard)

- Dual Fuel Burner (Gas and Oil, Low NOx, <10ppm)

- Exhaust Pressure Drop : 3 – 8 Inch W.C.

- Exhaust Temperature: 560-990 F

- Cooling / Heating / Domestic Hot Water

BHE Model, Hot (Jacket) Water and Exhaust

- Capacity: 30-3300 ton

- Hot Water Temperature: 160-220 F (Standard)

- Exhaust Pressure Drop: 3 – 8 Inch W.C.

- Exhaust Temperature: 580-1200 F

BZHE Model, Hot (Jacket) Water and Exhaust + Direct Gas Fire

- Capacity: 30-3300 ton

- Gas Pressure: 2.3-7.3 Psi (Standard)

- Dual Fuel Burner (Gas and Oil, Low NOx, <10ppm)

- Exhaust Pressure Drop : 3 – 8 Inch W.C.

- Exhaust Temperature: 580-1200 F

- Hot Water Temperature: 190-220 F (Standard)

Package Chiller (Enclosure, Pump System and Cooling Tower included)

- Direct Fire/Hot water/Steam/Exhaust

- Capacity: 40-2200 ton

- Gas Pressure: 2.3-7.3 Psi (Standard)

- Dual Fuel Burner (Gas and Oil, Low NOx, <10ppm)

- Cooling / Heating / Domestic Hot Water

Solar Driven (Solar Driven with Gas Burner back up)

- Capacity: 40-1000 ton

- Hot Water: 160-350F

- Gas Pressure:2.3-7.3 Psi (Standard)

- Dual Fuel Burner

- Cooling Only

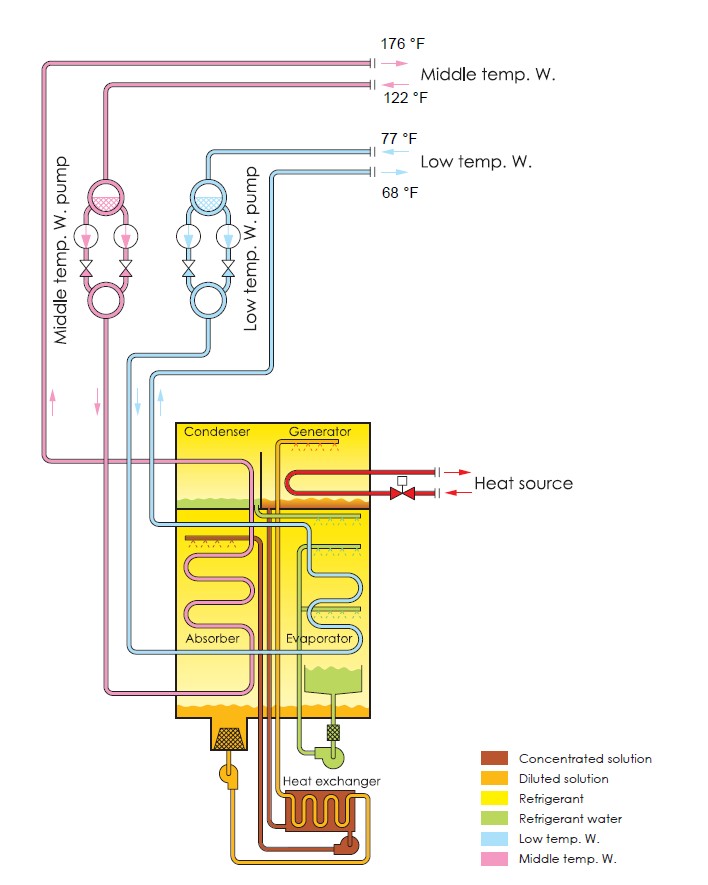

Brief Introduction to BROAD Absorption Heat Pump

It is universally accepted that water flows from high position to low position, as well heat transfers from high temperature to low temperature. After the invention of water pump, water can be pumped to higher position with energy input. The same principle has been applied to heat pump. With power (electricity or thermal energy) input, heat can be moved from low temperature to high temperature. BROAD Absorption Heat Pump is a device driven by thermal energy (steam, hot water, exhaust or NG) which moves heat from low temperature to high temperature.

Absorption heat pump and chiller are like twins, because they have the same structure and working principle, but application is different. A chiller is used to make chilled water, and reject heat through cooling water. An absorption heat pump recycles heat from low temperature heat source, to produce high temperature water. For typical application, conditions such as low temperature heat source and heating demand are different, so absorption heat pump has a wide rarge of working conditions. Compared with an electric heat pump, absorption heat pump has below advantages:

• Uses industrial waste heats, exhaust etc. as its input power

• Uses water as refrigerant instead of CFCs, HCFCs, HFCs

• Stable heating performance, endurable to ambient interruptions, no auxiliary heating equipments

• Higher heating temperature, temperature difference, and wilder applications

Absorption heat pump heating capacity comes from driven energy and low temperature waste heat with a heating efficiency 2~3 times higher than a boiler. The low temperature waste heat is common in industrial processes (like industrial cooling water, boiler exhaust gas etc.) and in nature world (like surface water, ground water etc.). BROAD Absorption Heat Pump is driven by waste heat with remarkable energy savings and payback. It has been installed in many countries around the world such as China, South Korea, Denmark, Belarus, Thailand and Austria.

Typical Applications

-

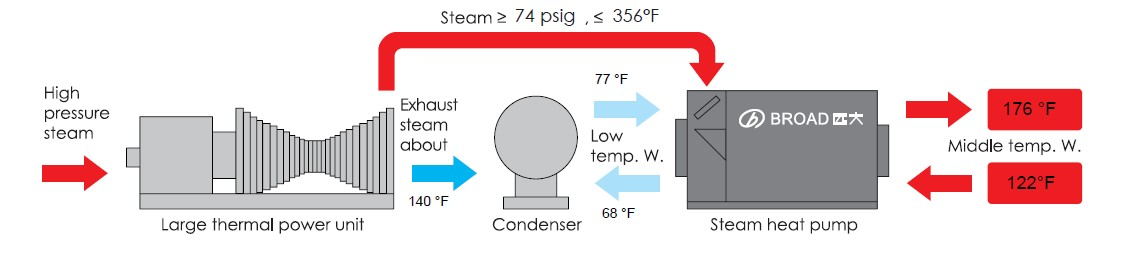

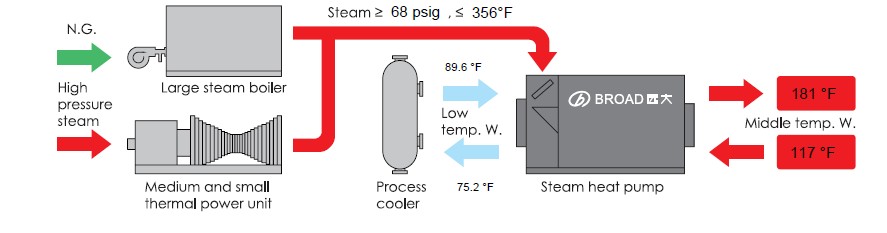

Thermal Power Plant Heat Pump — System Energy Saving by 15~20%

• Low temp. waste heat: cooling water from power plant (59 ~ 86 ºF)

• Driving heat source: steam from large scale steam turbine

• Typical application: a paper factory in Thailand, recovers 3.3 MW waste heat from cooling water to produce 185 ºF middle temp. water to preheat make up water. Two power plants in South Korea, recovers 48 MW waste heat from cooling water to produce 176 ºF middle temp. water for district heating

2. Industrial Process Heat Pump – Heating Energy Saving by 41%

- Low temp. waste heat: waste water heat from dyeing mill (about 86ºF), cooling water from air conditioning (about 98.6ºF), cooling water from steel works (about 104 ºF), heat from brewery process (about 122 ºF), heat from oil field (about 122 ºF), cooling water from coke plant (about 104 ºF or 73.4 ºF)

- Driving heat source: steam from large scale steam boiler or small & middle – sized steam turbine, natural gas, high temp. hot water

- Typical application: an eco-park in South Korea, recovers 24 MW heat from dyeing process to produce 181 ºF middle temp. water for district heating

The world’s biggest daily chemicals manufacturer, which recovers 1.2 MW heat from air conditioning cooling water to produce 190 ºF middle temp. water for process heating

A district heating company in Austria, recovers 2.3 MW heat from steel works cooling water to produce 185 ºF middle temp. water for district heating

A famous Chinese liquor manufacturer, recovers 1.7 MW heat from brewery process to preheat boiler makeup water up to 176 ºF

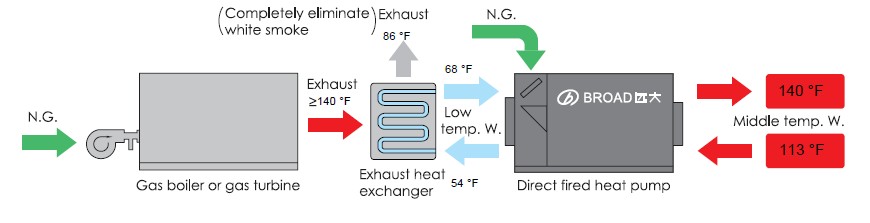

3. Exhaust Heat Pump – System Energy Saving by 8-15%

- Low temp. waste heat: exhaust from boiler, gas turbine, direct fired absorption chiller etc. (140 ~ 356 ºF)

- Driving heat source: natural gas, high temp. hot water, high temp. exhaust etc.

- Typical application: a biomass district heating center in Denmark, recovers 3 MW heat from biomass boiler exhaust to produce 185ºF middle temp. water for district heating China 12th National Games Center recovers 2.3 MW heat from 2*3, 300 RT BROAD direct fired absorption chillers’ exhaust to produce 140ºF middle temp. water for building heating

A district heating center in Beijing recovers 4.7 MW heat from 3*40 ton boilers’ exhaust to produce 140ºF middle temp. water for district heating

An energy plant in South Korea, recovers 24 MW heat from 2*77 MW gas turbines exhaust to produce 142 ºF middle temp. water for district heating

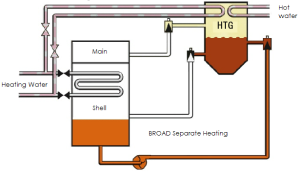

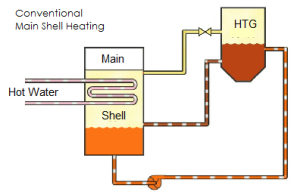

BROAD Absorption Heat Pump Diagram

Unique Technologies

Your Content Goes Here

Chiller Performance Validation

Broad Chillers are Factory Tested.

Broad Chillers are Factory Tested.

In North America, it became common to perform test electric chillers in the 1980s when manufacturers were making great strides in improving energy efficiency.

When CFCs and HCFC were phased out through the Clean Air Act in the 1990s many customers requested proof of performance as the switch to new HFC refrigerants yielded performance that was less predictable.

The history of Absorption Chillers in North America was to never run a unit test before shipment. There were various explanations of why this was “not a good idea”. The primary obstacle was the cost to set up a test stand that could deliver a wide variety of thermal heat sources to prove performance at a specific customer requirement. Another factor was time on the test stand that was required to perform an absorber test. To charge a chiller with LiBr Solution typically takes much longer than a chiller that requires chemical refrigerants. Water is the refrigerant in an absorber and when mixed with LiBr the “solution” is typically removed before shipment as modern absorption chillers are put under a protective nitrogen charge.

Over the years this lack of factory testing resulted in many projects that did not meet customer expectations with regard to design tons or Coefficient of performance (COP).

The demands of high-performance buildings today can be met regardless of what chiller technology is applied in the facility.

The Benefits of Factory Testing:

The Benefits of Factory Testing:

Owner: Ensures the chiller will yield the operating performance characteristics as designed. It can also be a great opportunity for the operator to learn about the unit which will be cooling or heating the building and to become an expert in the operation of the absorber.

Design Engineer: The only way to really validate that the chiller supplied is meeting the design specification requirements. Field testing can be extremely challenging and expensive to replicate.

Contractor: Lowers risk of system issues and eliminates field verification of chiller performance which can be very time intensive and difficult to accomplish.

What you will see on your visit:

|

Column 2 | |

|---|---|---|

| Column 1 Value | Column 2 Value | |

| Column 1 Value 2 | Column 2 Value 2 | |

| Column 1 Value 3 | Column 2 Value 3 | |

| Column 1 Value 4 | Column 2 Value 4 | |

| Column 1 Value 5 | Column 2 Value 5 | |

| Column 1 Value 6 | Column 2 Value 6 | |

| Column 1 Value 7 | Column 2 Value 7 | |

| Column 1 Value 8 | Column 2 Value 8 |

- Processing Center

- Laser Cutting Machine

- Digital Cutting Machine

- Digital Tube Bending Machine

- Tube Sheet Robotic Welding

- Robotic Shell Welding System

- Welding Robot Working Stations

- Auto-Submerged Arc Welding

- Absorption Chiller Production Line

- Robot Painting Lines

- Whole Unit Shot-Blasting

- Optical Emission Spectrometer

- Auto Material Testing Machine

- Whole Unit Testing Platform

- Atomic Absorption Spectrometer

- Helium Inspection System

- Control Cabinet Testing

Trusted Customers

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco.

Get A Service Today

At vero eos et accusamus et iusto odio dignissimos ducimus qui blanditiis praesentium voluptatum deleniti atque corrupti quos dolores et quas.