Providing cooling with fuel saves 4-time energy conversions and doubles energy efficiency

The technology of providing cooling from fuel is invented by BROAD from scratch which counters to the common sense. It has broken the monopoly of providing cooling from electricity and has been sold all over the world in just a few years. Why? Because we’ve digested the second law of thermodynamics: with each energy conversion, there is always energy loss. We understand electric aircons require five energy conversions to produce the cool air. They are fuel → thermal energy → mechanical energy → electric energy → mechanical energy → cold air. While BROAD directly provides cooling in one energy conversion, they energy efficiency is undoubtedly doubled.

What’s more, the separate heating technology invented by BROAD combines cooling, heating and hot water in one chiller, successfully eliminating the threat of boiler explosion accompanying electric aircon operation.

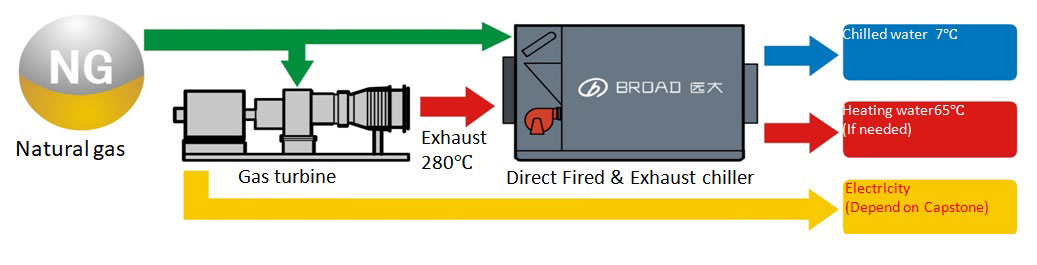

COOLING-HEATING-POWER (CHP) SYSTEM

Achieves Zero Emission with Exhaust Heat as Power source

For more than 100 years, thermal power plants are far from urban areas and waste heat cannot be utilized. The energy loss from voltage fluctuation and long-distance power transmission has reached 2/3 in vain, but this centralized energy model has been regarded as reasonable enough all the time. In 1999, BROAD invented the distributed energy model – the CHP System powered by exhaust heat from turbine generator. This system has been applied in more than 70 countries and has at least doubled the energy efficiency of each project, which equals to zero energy cost for cooling and heating. With the growing awareness of climate change crisis, distributed CHP system will ultimately take place of bulk grid, just as mobile communications will fully take over wired communications.

PACKAGED DISTRIBUTION SYSTEM

Saves 3/4 energy consumption than that of traditional ones

In traditional central aircon system, the supply and distribution system of cooling water, chilled water and hot water consumes 1/3 of the whole system’s energy. To correct this apparent unreasonable phenomenon, BROAD invented the packaged distribution system which saves an average of 3/4 energy consumption instantly. Meanwhile, the reliability of the distribution system has been improved to the same level as that of a chiller. This incredible energy saving miracle is indeed not mysterious, it’s attributed to the zero-resistance filter and intelligent control technology BROAD has invented. The core is, we need the solutions of the 21st century to solve the problems of the 21st century, and that is, to replace ”blind design” with industrial research, and to replace on-site construction with factory production.

BROAD SUSTAINABLE BUILDING (BSB)

Improves human life quality with buildings

For the past century, all walks of life have undergone tremendous changes, with the construction industry as the only exception – designers working behind the closed doors, unfixed contractors and migrant workers, and ”ants moving” construction mode. Whether in developing or developed countries, they are all alike. Since 2009, BROAD has invested RMB 4 billion to the invention of Sustainable Buildings featuring industrialized building R&D, streamlined production, container-like transportation and standardized installation, reaching no collapse in 9-magnitude earthquake, 90% factory-made, 5 times more energy saving and 100 times better air purification. It has advanced the world architecture technology 100 years forward, and has improved the living quality of mankind overall. When the video of ”a 57F building constructed in 19 days” went viral in 2015, people with high sensitivity are aware that the world history is about to be changed dramatically.

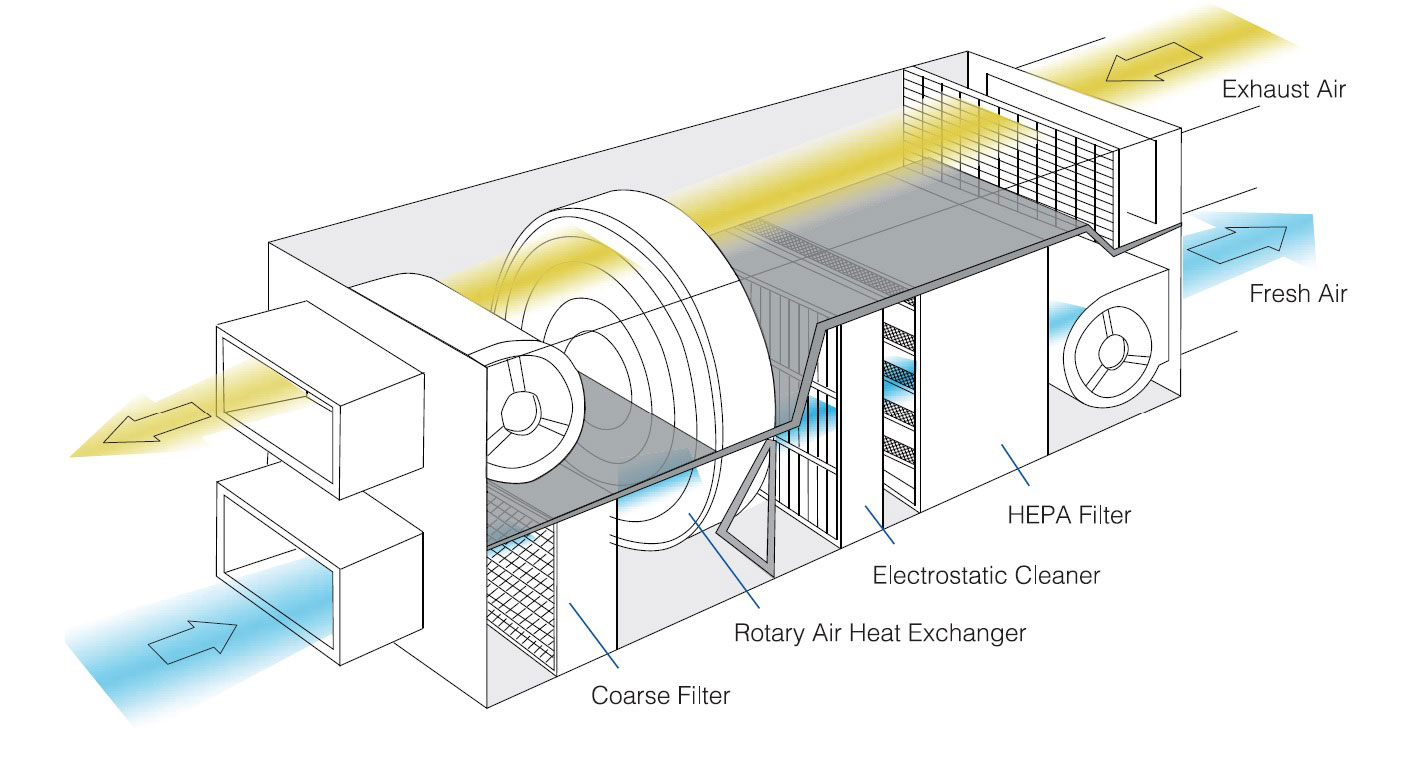

CLEAN FRESH AIR MACHINE

Easily cleans indoor air 100 times better than that outdoors

Perhaps nobody else in the world has ever thought of making the indoor air 100 times cleaner than that outdoors. However, BROAD made it possible in an affordable cost for common people. BROAD Clean Fresh Air Machine filters PM2.5 by 99.9%, and its ventilation power consumption is much lower than that of traditional products. Chinese people keep complaining about PM2.5, but the fact is, even people in developed countries also live in rooms with heavy PM2.5 and oxygen deficiency: indoor air pollution has become a common challenge for mankind. BROAD Clean Fresh Air Machine not only provides solution to the global challenge, but also recovers heat which drastically reduces aircon investment and operation cost. In extreme cold and hot areas, it can even operate at negative cost. A real human-oriented technology is the one that is affordable to common people.

AIRPRO MASK

Protects people from air pollution in any filthy environment

Today, wearable technologies are everywhere, but we can rarely find what we really need, except the rechargeable, affordable and extremely light super air purifier – BROAD AirPro Mask. It can filter PM2.5 by 99%, completely irradiate pollutants. It can also enlarge respiratory capacity, providing people with more comfort and energy. Although being small, the BROAD AirPro Mask is the shelter in smoggy weather, the support for miners, construction workers and medical personnel for epidemic diseases, as well as the hope of survival for respiratory patients.

GLOBAL INTERNET MONITORING SYSTEM

The first company that serves central aircon customers with a thinking of ”Internet+”

Several months after witnessing the paralysis of an entire building caused by an unexpected shutdown of central aircon, we invented a remote monitoring technology that collects information through telephone lines, and enables every non-electric aircon user to enjoy a 24/7 service. Today, when reviewing this invention developed 19 years ago in the era of ”Internet+” , we are surprised to find out that BROAD has made itself the pioneer of ”Internet +”

FACTORY ACCEPTANCE TEST (FAT)

In North America, it became common to perform test electric chillers in the 1980s when manufacturers were making great strides in improving energy efficiency. When CFCs and HCFC were phased out through the Clean Air Act in the 1990s many customers requested proof of performance as the switch to new HFC refrigerants yielded performance that was less predictable.

The history of Absorption Chillers in North America was to never run a unit test before shipment. There were various explanations of why this was “not a good idea”. The primary obstacle was the cost to set up a test stand that could deliver a wide variety of thermal heat sources to prove performance at a specific customer requirement. Another factor was time on the test stand that was required to perform an absorber test. To charge a chiller with LiBr Solution typically takes much longer than a chiller that requires chemical refrigerants. Water is the refrigerant in an absorber and when mixed with LiBr the “solution” is typically removed before shipment as modern absorption chillers are put under a protective nitrogen charge.

The history of Absorption Chillers in North America was to never run a unit test before shipment. There were various explanations of why this was “not a good idea”. The primary obstacle was the cost to set up a test stand that could deliver a wide variety of thermal heat sources to prove performance at a specific customer requirement. Another factor was time on the test stand that was required to perform an absorber test. To charge a chiller with LiBr Solution typically takes much longer than a chiller that requires chemical refrigerants. Water is the refrigerant in an absorber and when mixed with LiBr the “solution” is typically removed before shipment as modern absorption chillers are put under a protective nitrogen charge.

Over the years this lack of factory testing resulted in many projects that did not meet customer expectations with regard to design tons or Coefficient of performance (COP). The demands of high-performance buildings today can be met regardless of what chiller technology is applied in the facility.

Owner: Ensures the chiller will yield the operating performance characteristics as designed. It can also be a great opportunity for the operator to learn about the unit which will be cooling or heating the building and to become an expert in the operation of the absorber.

Owner: Ensures the chiller will yield the operating performance characteristics as designed. It can also be a great opportunity for the operator to learn about the unit which will be cooling or heating the building and to become an expert in the operation of the absorber.

Design Engineer: The only way to really validate that the chiller supplied is meeting the design specification requirements. Field testing can be extremely challenging and expensive to replicate.

Contractor: Lowers risk of system issues and eliminates field verification of chiller performance which can be very time intensive and difficult to accomplish.